This guide provides a practical overview of migration testing for plastic food-contact materials in the EU, explaining how substances can transfer into food and the relevant regulatory limits under Regulations (EC) 1935/2004 and (EU) 10/2011. It covers key laboratory techniques, including overall and specific migration testing, NIAS screening and challenges with multilayer or printed materials. The guide also offers best practices, sample preparation advice and a compliance checklist to help companies ensure their packaging meets EU safety standards.

Table of Contents

Introduction

What Is Chemical Migration in Packaging?

Chemical migration is the transfer of molecules (constituents) from a packaging material into food or into a food simulant used for testing. In plastics these migrants include residual monomers, additives (plasticizers, antioxidants), reaction products, impurities and non-intentionally added substances (NIAS) such as degradation/by-products and oligomers. Migration is driven by concentration gradients and accelerated by higher temperature, longer contact time and the nature of the food (fatty, acidic, alcoholic).

Why It Matters

Migrants may alter food quality (taste, odor, appearance) and more importantly, pose toxicological risks if they are hazardous or present above safe levels. Demonstrating controlled migration is essential both for consumer safety and for legal market access in the EU. The outcome of migration testing feeds the Declaration of Compliance (DoC) that the manufacturer/supplier must supply downstream.

Regulatory Background (what to cite and why)

The EU regulation framework for food contact materials (FCMs) is built on a general framework and material-specific rules:

- Regulation (EC) 1935/2004: the Framework Regulation for all FCMs, it lays down the general safety/inertness requirement (materials must not release constituents that endanger health or change the composition/organoleptic properties of food).

- Commission Regulation (EU) 10/2011: Plastics-specific rules (the “plastics regulation”), which defines the Union list of authorized monomers/additives, specific migration limits (SMLs), and the overall migration limit (OML) and test conditions for plastics. EN 1186 standards are referenced for selection of overall migration test methods and conditions.

- The plastics regulation is actively updated (e.g., latest amendment of Commission Regulation (EU) 2025/351 to further refine purity/labelling/recycling and NIAS-related requirements) so DoCs must be kept current with legislative changes.

Test Methods & Techniques

The migration testing strategy consists of two different analyses; overall migration (bulk inertness) and specific migration (individual regulated substances and targeted analytes), supported by analytical screening for NIAS. The choice of analytical technique depends on volatility, polarity and whether the target is elemental (metals) or organic.

Overall migration (OM)

- Purpose: Measure the total mass of non-volatile substances that migrate from a plastic into a specified food simulant under prescribed “worst-case” conditions. OM is used as a first-line check of material inertness.

- Regulatory reference & limit: For plastics the overall migration limit is 10 mg / dm² of food contact surface, as set in (EU) 10/2011. OM testing according to 10/2011 (and its referenced standard EN 1186 series) is effectively a legal prerequisite for placing a plastic material on the EU market.

- Test selection: EN 1186-1 provides guidance on selecting simulants and time/temperature combinations appropriate to intended use (long-term at room temperature, hot-fill, refrigerated storage, etc.). Food simulants (A, B, C, D1, D2 etc.) and harmonized test conditions in 10/2011 map to typical use cases. These define OM test cases (e.g., OM2 = long-term storage, 10 days at 40 °C – see 10/2011 for the exact mapping). EN 1186 (EN 1186-2 – EN 1186-9) describes the practical methods (like immersion, contact area calculations).

Specific Migration

- Purpose: Quantify migration of individually listed substances (monomers, additives, degradation products) that have SMLs in 10/2011 (or specific restrictions).

- Approach: The preparation of the sample is done the same way as for the overall migration procedure (contact times and temperatures, single or double side contact) and then, the simulant is tested by a targeted analytical method to measure each substance against its SML. Typical targets include certain monomers, metals, plasticizers, regulated additives and Primary Aromatic Amines (PAAs).

- Analytical Techniques (when to use what)

- GC-MS (Gas Chromatography-Mass Spectrometry): best for volatile and semi-volatile organic migrants (low-to-medium molecular weight organics). GC-MS is the industry workhorse for NIAS screening because extensive spectral libraries speed identification of many small NIAS.

- LC-MS / LC-MS/MS (Liquid Chromatography-Mass Spectrometry): necessary for non-volatile, polar or higher molecular weight migrants (oligomers, polar additives, some degradation products). LC is the technique of choice when GC is not suitable due to thermal instability or polarity.

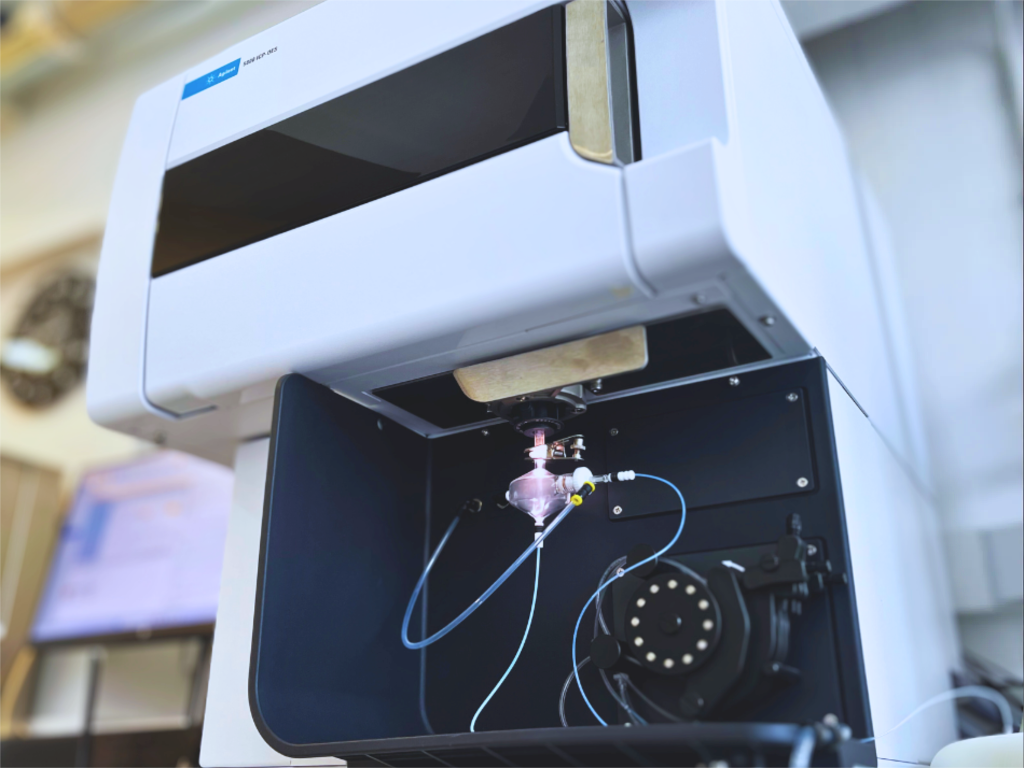

- ICP-OES or ICP-MS (Inductively Coupled Plasma – Optical Emission / Mass Spectrometry): used for elemental analysis (metals) (e.g., heavy metals, catalyst residues, or intentionally used metallic additives). ICP methods provide low detection limits and multi-element capability.

- Headspace-GC or purge-and-trap GC: for very volatile migrants (e.g., solvents, monomers) where headspace sampling is appropriate.

In short, use GC-MS for volatile/semivolatile species and initial NIAS screens (leveraging spectral libraries), LC-MS for non-volatile NIAS and oligomers, and ICP-OES/ICP-MS for metals.

NIAS (Non-Intentionally Added Substances) – Screening & Risk Assessment

- Definition & importance: NIAS are impurities, side-products, degradation products or reaction intermediates not intentionally added but present in the final article. They are a major challenge because they are often unknown and not listed in the Union list, yet they can migrate. ILSI and other bodies have published guidance on the risk assessment and analytical strategies for NIAS.

- Analytical practice: Many NIAS are small, volatile or semi-volatile, hence GC-MS is commonly used for initial NIAS screening due to extensive mass spectral libraries that aid tentative identification. For NIAS that are larger, thermally labile or polar, LC-MS (especially high-resolution MS) is required. A combined approach (GC + LC) offers the broadest coverage. High-resolution accurate-mass instruments and in-house or commercial libraries support the identification. In addition, toxicological assessment follows identification, including threshold of toxicological concern (TTC) approaches when full toxicological data are absent.

Material-Specific Challenges

Plastic packaging is not homogeneous, since structure, coatings, inks and layer composition change migration behavior and analytical needs.

Multilayer laminates (including functional barriers)

- Considerations: Multilayers commonly include barrier layers (EVOH, PA), adhesives, tie layers and outer layers printed or coated with pigments/inks. Inner food-contact layers may be thin, and migrants can originate from outer layers or adhesives and diffuse through barrier layers under certain conditions. Functional barriers may slow or prevent migration but cannot be assumed impermeable without evidence.

- Testing implications: Entire articles must be considered. If a plastic layer is in direct contact with food, the material (and potentially other layers) is subject to the plastics regulation testing requirements; adhesives and inks that can migrate into the food must be included in risk assessment and testing. Worst-case geometries and contact areas must be used, and testing may be needed to simulate actual construction (e.g., filled pouches or cups) rather than flat coupons.

Rigid Plastics (Bottles, Trays, Containers)

- Considerations: Rigid articles often have lower surface-area-to-volume ratios but can pose migration risks when used for hot-filled products, or when exposure involves repeated use and washing (repeated migration may differ from single-use behavior).

- Testing: Ensure test conditions replicate the real article (fill tests for bottles, immersion for trays). For repeated-use articles, migration testing sometimes requires multiple consecutive migration cycles to reflect accumulation or exhaustion behavior.

Plastics With Inks / Barriers / Coatings (even if not in direct contact)

If the packaging contains inks, coatings or barrier layers and any plastic layer that could reasonably affect the food (i.e., is in direct contact or can migrate through), it must be assessed as a plastic FCM under 10/2011 (the presence of inks on the outside does not automatically exclude migration potential). Inks and coatings are common sources of NIAS (residual monomers, pigment impurities) or other substances (primary aromatic amines, solvents and photoinitiators) and must be included in the supply-chain information exchange and testing plan.

Practical Considerations & Best Practices

This section focuses on practical steps companies should take so migration testing is meaningful, defensible and aligned with EU Regulations.

Detection Limits and Sensitivity

- Why it matters: Specific migration limits (SMLs) and toxicological thresholds may be very low (μg/kg range for certain genotoxic impurities). A lab’s limits of quantification (LOQ) must be below the applicable regulatory threshold (or low enough that non-quantified means “below SML”). You may ask labs to report LOD (detection)/LOQ (quantification) alongside reported concentrations.

- What to request: Method LOD/LOQ, calibration range, and whether the lab’s methods are appropriate for the specific SML in question. For NIAS screening, confirm the lab’s mass spectrometer resolution and library coverage. Accreditation and participation in proficiency tests are good indicators of capability.

Choosing Accredited Laboratories

- Accreditation: Prefer laboratories accredited to ISO/IEC 17025 for migration testing and the specific analytical methods (GC-MS, LC-MS, ICP-MS). Accreditation supports traceability and confidence in results. You can ask for scope of accreditation and for evidence of participation in inter-laboratory comparisons for migration tests (proficiency testing), as mentioned earlier.

- Practical checks: Request recent method LOD/LOQ, example reports, and whether the lab understands EU test cases (EN 1186-1, EU 10/2011). Confirm they can analyze metals (ICP), PAAs and NIAS using GC-MS/LC-MS as needed.

Impact of Temperature, Storage and Use-conditions

Before requesting any analysis, decide and share the worst-case scenario with your lab, by providing the exact or conservative maximum storage temperature, intended shelf life, whether the food is fatty or acidic, filling temperature (e.g., hot fill), and whether the article is reusable/washable. Migration is strongly temperature and time-dependent. Additionally, test conditions in (EU) 10/2011 are tied to intended uses. Labs cannot choose appropriate test conditions without this information.

Standard Practice (current industry baseline)

For plastic FCMs the commonly accepted baseline of tests includes:

- Overall migration (global migration) per Regulation (EU) No 10/2011 and EN 1186 guidance (appropriate simulants and worst-case conditions)

- Specific migration of metals (ICP techniques) for metals included in Annex II of (EU) 10/2011

- Specific migration of Primary Aromatic Amines (PAAs) where azo dyes/pigments and aromatic adhesives (e.g. 2-component polyurethane) are present. These substances are also included in Annex II of (EU) 10/2011

- NIAS screening (GC-MS) for volatile and semi-volatile NIAS (most volatile codes) and LC-MS for non-volatile NIAS/oligomers

Conclusion & Checklist

Take-home Best Practices (short summary)

- Treat migration testing as use-case driven: define the worst foreseeable conditions and use those as the basis for OM and specific migration tests

- Combine overall and specific migration testing with targeted NIAS screening (GC + LC) and metal analysis (ICP) to get complete coverage

- Work with ISO/IEC 17025 accredited labs that can demonstrate appropriate LOD/LOQ and provide detailed test reports

- Keep documentation and supplier declarations of compliance (DoCs) up to date and align migration re-testing with regulatory changes (e.g., recent amendments to 10/2011 and related acts)

PDF – Practical Compliance Checklist for Companies

References

- European Commission (2004) Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. Available at: https://eur-lex.europa.eu/eli/reg/2004/1935/oj (Accessed: 2 December 2025).

- European Commission (2011) Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food. Available at: https://eur-lex.europa.eu/eli/reg/2011/10/oj (Accessed: 2 December 2025).

- European Commission (n.d.) Food Contact Materials – Plastic Recycling and Food Safety. Available at: https://food.ec.europa.eu/safety/chemical-safety/food-contact-materials/plastic-recycling_en (Accessed: 2 December 2025).

- EFSA (2022) Risk assessment of food contact materials. EFSA Journal, e200920. Available at: https://www.efsa.europa.eu/en/efsajournal/pub/e200920 (Accessed: 3 December 2025).

- ILSI Europe (2015) Koster, S. et al. Guidance on Best Practices on the Risk Assessment of Non-Intentionally Added Substances (NIAS) in Food Contact Materials and Articles. ILSI Europe Report Series 16/07. Available at: https://ilsi.eu/publication/guidance-on-best-practices-on-the-risk-assessment-of-non-intentionally-added-substances-nias-in-food-contact-materials-and-articles/ (Accessed: 2 December 2025).

- ILSI Europe (n.d.) Guidance on NIAS Best Practices. Available at: https://www.pac.gr/bcm/uploads/10-guidance-on-best-practices-on-the-risk-assessment-of-nias.pdf (Accessed: 2 December 2025).

- CEN (2022) EN 1186-3:2022. Materials and articles in contact with foodstuffs – Plastics – Test methods for overall migration in evaporable simulants. Available at: https://www.en-standard.eu (Accessed: 3 December 2025).

- CEN (2002) EN 1186-13:2002. Materials and articles in contact with foodstuffs – Plastics – Test methods for overall migration at high temperatures (100-175 °C). Available at: https://www.en-standard.eu (Accessed: 3 December 2025).